Simulation is where concepts become reliable decisions. Building on validated data, precise models, and defined requirements, we simulate real-world conditions to predict performance, identify risks, and optimize outcomes—before anything is built or manufactured. This allows us to test scenarios, compare variants, and understand complex interactions in a controlled, cost-efficient environment. The result is clarity: well-founded insights that reduce uncertainty, shorten development cycles, and enable confident technical and strategic decisions.

1. Hotrunner

One of the main influences to a good / bad part is the gating system. Commonly there are cold runner or hot runners be used. We focus in a high level of detail in a very early beginning of the project to balance the gating system to have a uniform filling in all cavities.

2. Filling

To get a first estimation what happens in the cavities we make a simple filling study. At this stage with no cooling implemented we get a larger understanding of the "problem" areas from your part.

3. Cooling Proposal

The possibility to create in our simulation software helps us to get a understanding which influence the cooling have to your part. We create the optimal cooling and start the next step of simulation to understand the thermal influences.

1. Hotrunner

One of the main influences to a good / bad part is the gating system. Commonly there are cold runner or hot runners be used. We focus in a high level of detail in a very early beginning of the project to balance the gating system to have a uniform filling in all cavities.

2. Filling

To get a first estimation what happens in the cavities we make a simple filling study. At this stage with no cooling implemented we get a larger understanding of the "problem" areas from your part.

3. Cooling Proposal

The possibility to create in our simulation software helps us to get a understanding which influence the cooling have to your part. We create the optimal cooling and start the next step of simulation to understand the thermal influences.

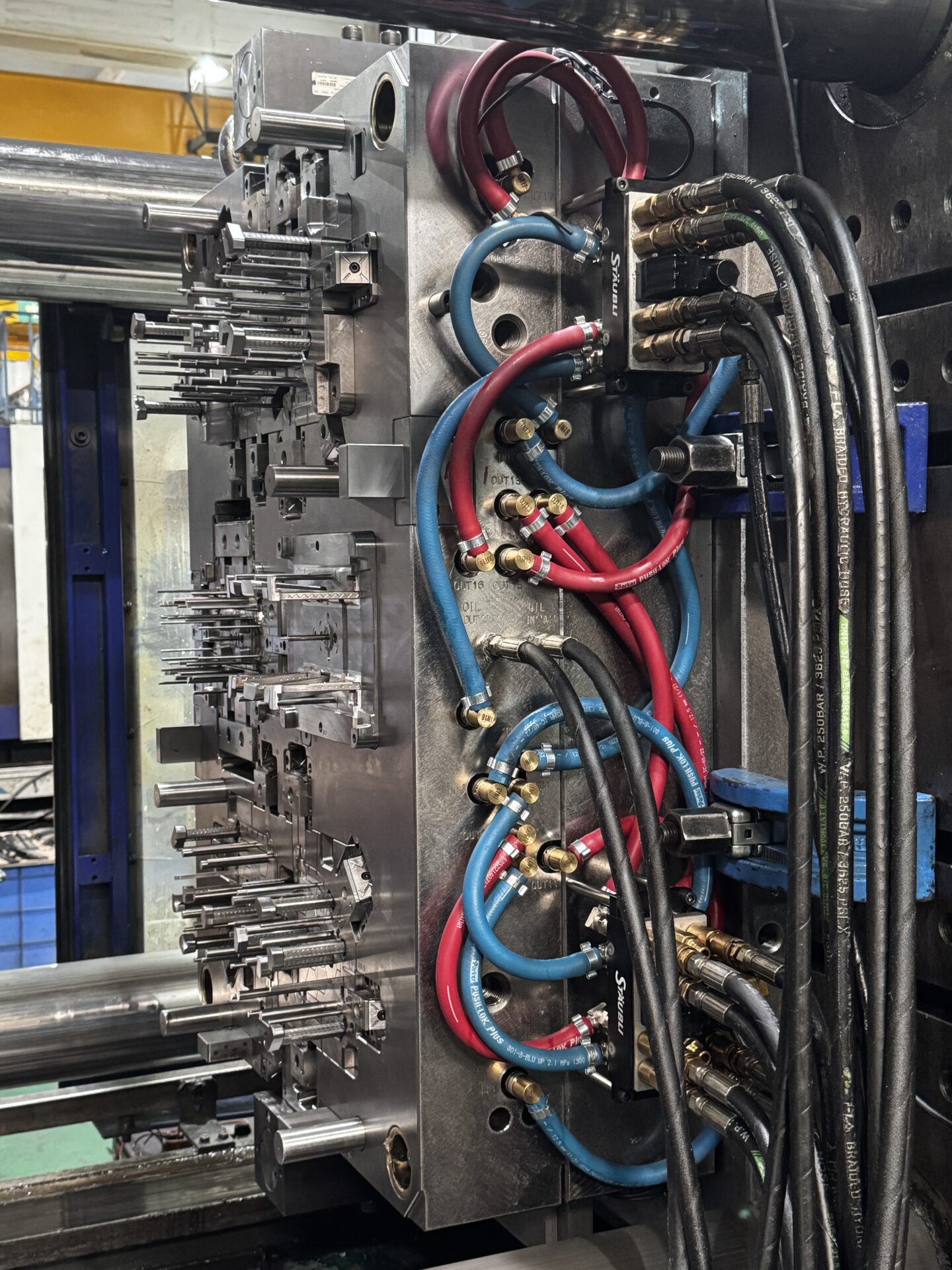

4. Real Cooling

We send our cooling proposal to the toolmaker, the toolmaker try to implement the optimal cooling in the tool. For sure this is in most of the cases not possible because of ejectors, inserts etc.

5. Mold Material

After we get the real cooling back out of the design we start to analyze this cooling. Flow length, and flow rate of each cooling channel will be checked. After an positive result we start the "real" simulation. Therefore we include the mold materials (Moldmax inserts, steel types with different thermal conductivity etc.) to get the real wall temperatures in each step of injection.

6. Reporting

A very clear report will be generated as PDF, pptx or a web based file. You will get an easy to understand result and a large understanding of your part.

4. Real Cooling

We send our cooling proposal to the toolmaker, the toolmaker try to implement the optimal cooling in the tool. For sure this is in most of the cases not possible because of ejectors, inserts etc.

5. Mold Material

After we get the real cooling back out of the design we start to analyze this cooling. Flow length, and flow rate of each cooling channel will be checked. After an positive result we start the "real" simulation. Therefore we include the mold materials (Moldmax inserts, steel types with different thermal conductivity etc.) to get the real wall temperatures in each step of injection.

6. Reporting

A very clear report will be generated as PDF, pptx or a web based file. You will get an easy to understand result and a large understanding of your part.

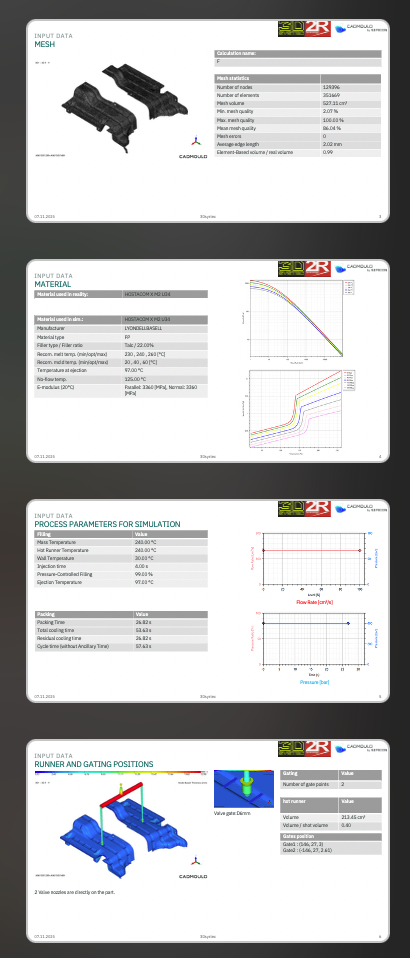

Your PDF-Reports:

We deliver comprehensive, clearly structured reports—available as PDF, PowerPoint, or interactive web-based formats—tailored to your project and stakeholders. Each report translates complex simulation results into easy-to-understand insights, supported by precise data, visualizations, and clear conclusions. This ensures full transparency and a deep understanding of your component or system, enabling reliable final reviews, early adjustments, and well-informed decisions before implementation.