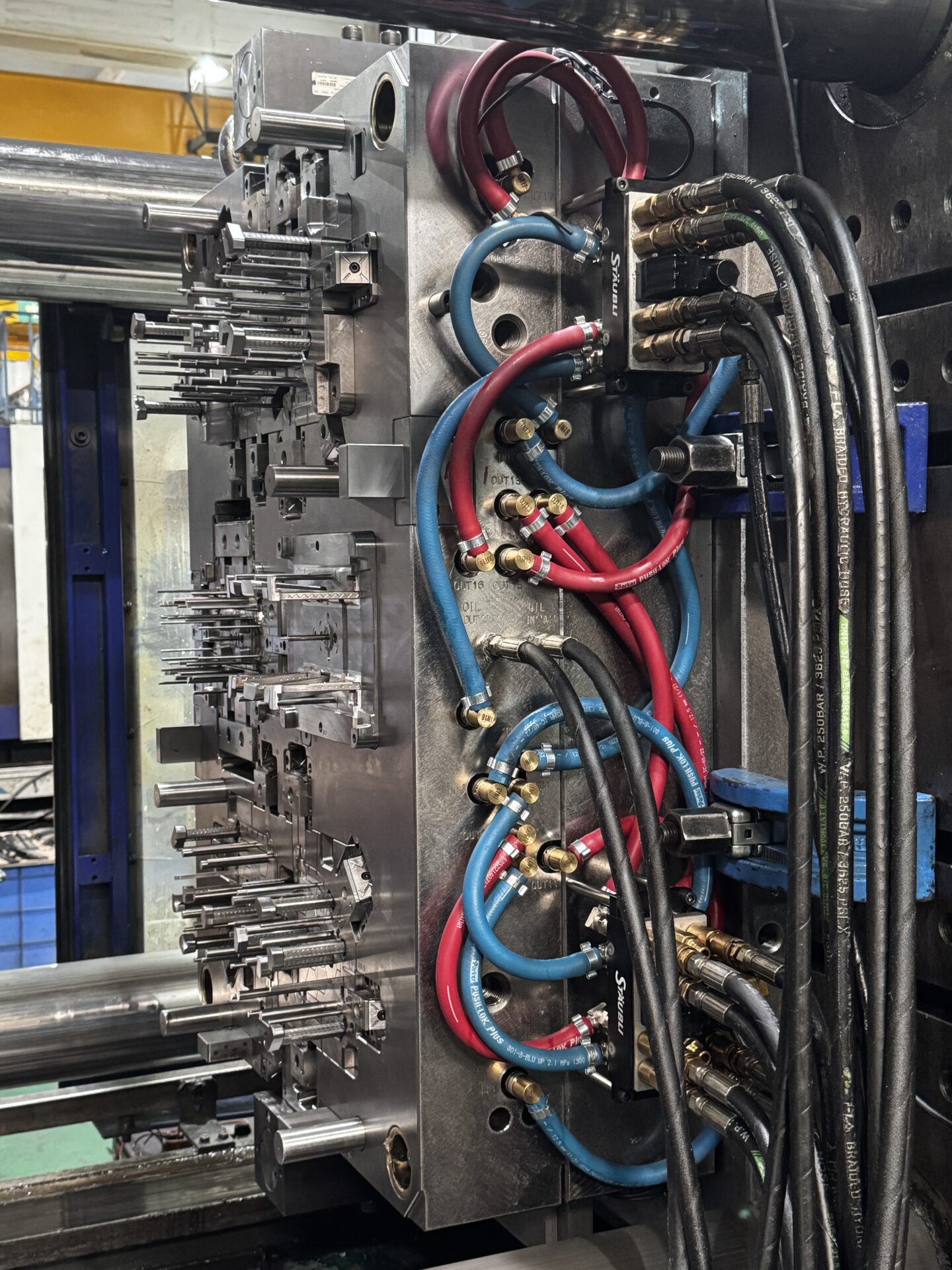

We have a team of experienced engineers and all possible equipment to make a successful trial.

Our engineers have 10 – 35 years experience in injection molding, we keep us always up to date with the newest technologies and equipment

Possibilities

Whether it’s the fast 3D scanning of large components you’re interested in, or high detailed 3D scanning of small complex components, with over 20 years industry experience, we have the technology and professional know how to provide you with the high quality, accurate data you need.

We do not just stop at high quality 3D scanning though. Once we have produced an accurate digital representation of your component, our CAD team can consult with you to create a complete digital model, or if you already have a CAD model and you want to inspect against this, our experienced team will discuss your requirements with you and produce the 2D and 3D inspection reports you need.

Tool reconstruction

Part reconstruction

Scanning of design CAD models for further processing

Documentation

Evaluation of 2D & 3D dimensions

Target / actual comparison

Full measurement report

Reverse engineering

Measurement fixtures / gauges

Features and Benefits

Our highly accurate 3D scanning systems can measure the most complex of free form components where traditional methods fall short. With high resolution and stereo camera configurations, millions of 3D point coordinates are calculated within seconds, in comparison with single point measurements from tactile measurement systems.

Our 3D measurement process is completely portable so completing the measurement of components, fixtures or machines on site is no problem at all.

The blue light technology in our 3D scanning systems enables us to have the greatest flexibility when it comes to measuring conditions.

To complement the non contact 3D scanning systems we can introduce our tactile probe measurement system for those hard to reach areas.

For ultimate accuracy for large measurements we can use our large scale CMM system to achieve very high global accuracy.

Capabilities

- High resolution 3D scanning

- Flexible measurement volumes

- Low sensitivity to environment lighting conditions

- Data density down to 0.012 mm

Quality and Inspection

Get a larger understanding of what your part is really up to.

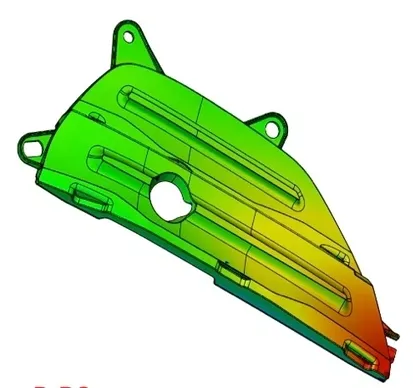

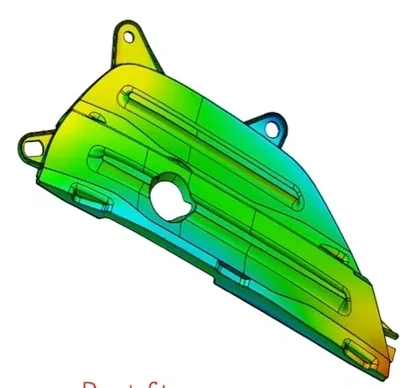

- Part to CAD Surface comparisons

- Full GD&T

- 2D & 3D Reporting

- and much more…

We scan

We introduce to CAD

We allign

Best Fit Alignment

R.P.S. Alignment