The thinking Company

3Dsystec is your single-source partner for precision tooling and injection molding. We integrate expert project management, cutting-edge inspection, and advanced engineering services to ensure your project’s success, every step of the way.

Navigating the gap between design and mass production is complex. At 3dsystec, we bridge that gap. We combine world-leading 3D measurement technology with deep industry expertise to give you absolute confidence in your parts.

Our comprehensive, „all-under-one-roof“ services eliminate delays and miscommunication, providing a seamless, consultative partnership.

// Our Integrated Services Include:

Precision Measurement & Inspection:

World-leading non-contact 3D scanning for accurate first-article inspection (FAI), quality control, and reverse engineering across all industries—from medical and aerospace to automotive and consumer goods.

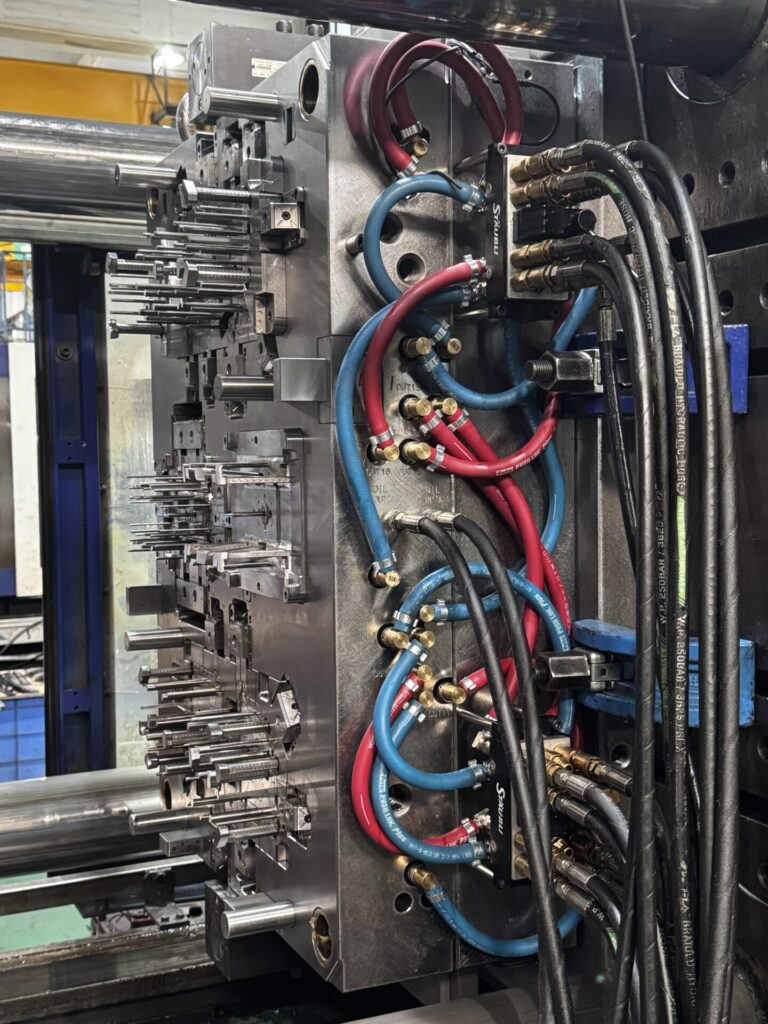

Tooling & Molding Management:

Expert project management from initial tool design through trial shots, rigorously managed according to your PPA.

Engineering & Production Support:

Full 3D CAD modeling and End-of-Arm-Tooling (EOAT) design to optimize your manufacturing line.

Measurement Fixtures:

Accelerate development with our professional Fixturesservices.

// Mission: Your Confidence.

To bridge the gap between design and production through experience and modern technology. We deliver clear, actionable results and consultative support, providing a true one-stop solution for all your tool and molding needs.

// 01

// Cost Efficiency

Simulation transforms validated data into actionable insight. By testing real-world conditions digitally, we evaluate performance, compare scenarios, and identify risks early—enabling confident decisions before implementation begins.

1. Hotrunner

One of the main influences to a good / bad part is the gating system. Commonly there are cold runner or hot runners be used.

2. Filling

At this stage with no cooling implemented we get a larger understanding of the "problem" areas from your part.

3. Cooling Proposal

The possibility to create in our simulation software helps us to get a understanding which influence the cooling have to your part.

4. Real Cooling

We send our cooling proposal to the toolmaker, the toolmaker tries to implement the optimal cooling in the tool.

5. Mold Material

Moldmax inserts, steel types with different thermal conductivity to get the real wall temperatures in each step of injection.

6. Reporting

A very clear report will be generated as PDF, pptx or a web based file. You will get an easy to understand result and a large understanding of your part.

// 02

// Transparency

We pair our team of dedicated experts with powerful, integrated systems to provide a seamless and transparent client experience. You will have 24/7 access to critical program information and schedules, backed by our constant support.

Our Commitment:

- 24/7 access to your project information

- dedicated Account Manager

- we speak english, german, spanish & mandarin

- you are welcome in our facilities

// 03

// Efficient & Repeatable

A scientific molding process is an efficient and repeatable molding process which is stable and reliable with a large processing window. Although there are many facets to a scientific molding process, the general attributes are as follows:

Our Process:

The process uses one injection speed to fill, whenever possible

The mold fills 95% to 98% full during first stage

All cavities are short shot during first stage

1 st stage fill is velocity-controlled and not pressure limited

Process uses 20% to 80% of the machine’s available shot size

Final cushion is approximately 10% of the overall shot size

// 04

// 3D Scan

A scientific molding process is an efficient and repeatable molding process which is stable and reliable with a large processing window. Although there are many facets to a scientific molding process, the general attributes are as follows:

Our Process:

We Scan

We introduce to CAD

We allign

You get easy to understand results

You get easy to understand results

// 05

// +100 Systems

Our clients rely on us for success because we provide:

At 3Dsystec, we are recognized experts in the design, engineering, and fabrication of precision End-of-Arm Tooling. Our capability spans the entire spectrum—from straightforward, two-vacuum-cup units to the simultaneous production of over 100 custom EOAT systems.

- Unmatched Experience: A deep knowledge base gained from executing projects of all scales and complexities.

- Extensive Component Inventory: Immediate access to a broad range of high-quality EOAT parts.

- Integrated In-House Services: Full-cycle support from our knowledgeable engineering team and skilled assembly technicians, all within our own manufacturing facility.

// 06

// Accuracy & Precision

Precision Isn't an Accident. It's Built In.

Stop trusting guesswork. Elevate your quality control, accelerate your R&D, and guarantee perfection with our professional-grade measurement fixtures.

- Lock in Accuracy: Eliminate human error and ensure every part, on every shift, is measured exactly the same way.

- Boost Your Throughput: Reduce setup and measurement time by up to 70%, getting your products to market faster.

- Empower Your Team: Intuitive designs mean any operator can perform expert-level inspections with minimal training.

- Protect Your Investment: Ensure compliance, reduce scrap and rework, and build a reputation for unwavering quality.

// 07

// BSJ Hotrunner

The Heart of Your Mold Deserves the Best. It Deserves BSJ Hotrunner.

At BSJ, we understand that your hot runner system is the critical link between your machine and a perfect part. That’s why we engineer every component for one purpose: peak performance and profitability.

Why BSJ Hotrunner is Your Competitive Advantage:

- Precision at its Core: Experience flawless gate quality and brilliant color changes with our balanced, uniform heating. Say goodbye to flow lines and hesitation marks.

- Designed for Your Success: From compact, high-cavitation molds to large technical parts, we offer custom solutions that fit your exact application.

- Durability You Can Depend On: We use only the highest quality materials and coatings to combat wear and corrosion, ensuring your system runs longer with less maintenance.

- A Partnership, Not Just a Product: Our collaboration doesn’t end with a sale. We provide expert technical support to ensure your project’s success from concept to continuous production.

3D

Systec

Headquarter

HuaYi Building No.9 Pingji Avenue,

NanWan, Residental District,

LongGang, Shenzhen,

+86 15919800262

w.bregenzer@3dsystec.de

Project & Design Office

Schiffgasse 2

92660 Neustadt / WN

+49 1713602438

karsten@3dsystec.de

3D Systec / Proforma

Service center for tools

Pro forma concept GmbH

Agricolastraße 1

01471 Radeburg

+49 1713602438

karsten@3dsystec.de

Technology Headquarter

Carretera San Miguel a Celaya KM 1.6

Bodega 7. Col. Villa de los Frailes. CP 37790,

San Miguel de Allende, Gto.

+52 415 1140883

info@2rtechnology.mx

3D Systec /

2R Technology

Service center tools up to 26 t

130 Satellite Blvd NE STE 300

Suwanee, GA 30024

+85270719817

w.bregenzer@3dsystec.de